|

Profinet EIP EtherCAT

EGD UDP RFM RtEthernet Tc-net S7 Modbus OPC iso Ads Siemens

AB,GE,Mitsubishi,Beckhoff,MOOG,Schneider,ABB,Alstom,Driver,Domestic

PLC,Special Board QDR quality data

recording (digital steel coil) centimeter and millisecond level, supports

32+clients online Equipment testing, fault

diagnosis, quality analysis, ikoPDA CHPDA PLC-PDA, No crack & call

similar system |

3rd PDA formats &

Rich proprietary features Global Standards,

Exceptional Value Simplified for Full Customization &

OEM with Open APIs Proven by Hundreds of |

||||||||||||||||||||||||||||||||

|

Process Data

Acquisition – CHPDA -- Detailed analysis of

quality manage & industrial big data sources -- Full stack develop & Fully intellectual property

owned |

|||||||||||||||||||||||||||||||||

|

46 |

|||||||||||||||||||||||||||||||||

|

47 |

|||||||||||||||||||||||||||||||||

|

56 PDA system scheme for converter, RH furnace, LF furnace in

steel plant |

|||||||||||||||||||||||||||||||||

|

64 S7-1200 as

both a PROFINET IO Controller and an IO Device |

|||||||||||||||||||||||||||||||||

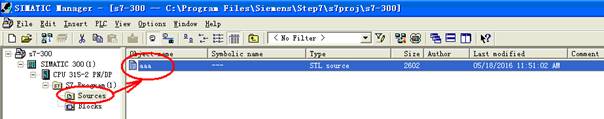

11

S7-300/400 standard ethernet

11.1

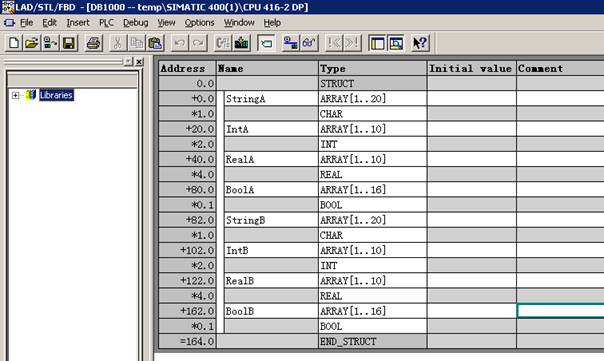

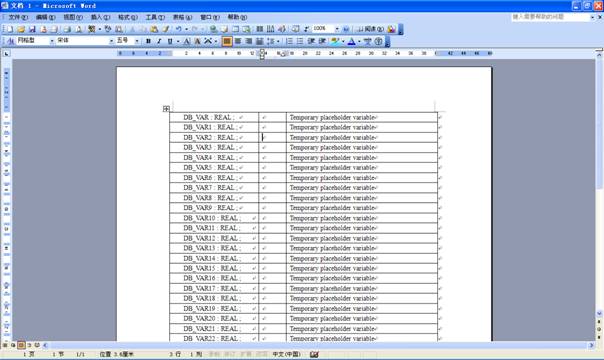

Define DB and assign values in PLC

Assign gathered data to a DB in PLC, send the whole to the PDA server, as follows.

Create Book1.csv with Excel, and establish the STL corresponding assignment statement with the last table, copy the content into the PLC function block. L ,65,, T,DB1000.StringA[1],//

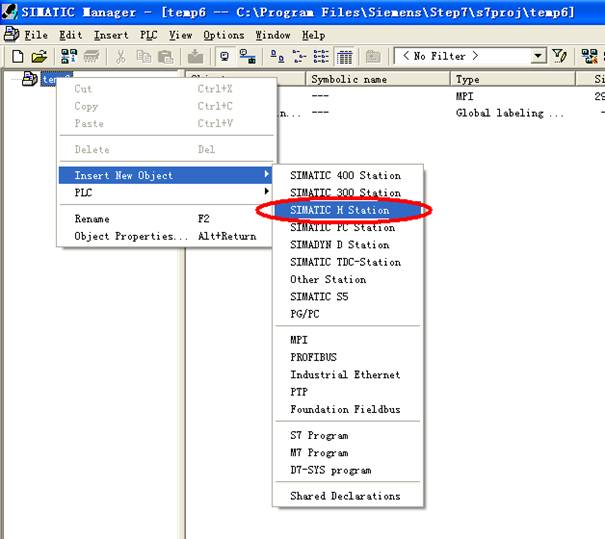

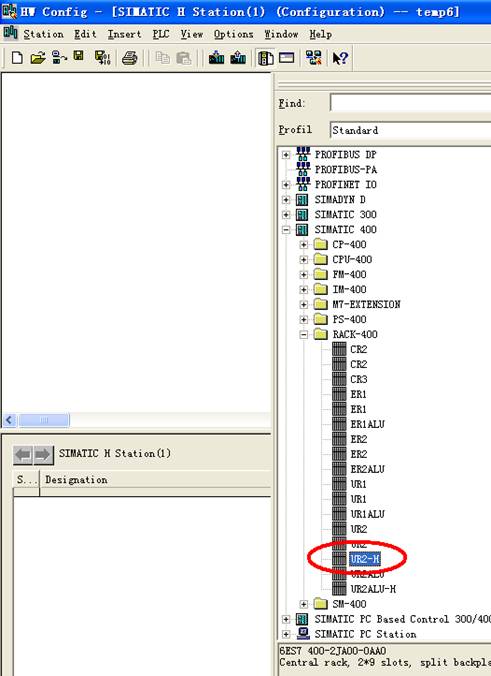

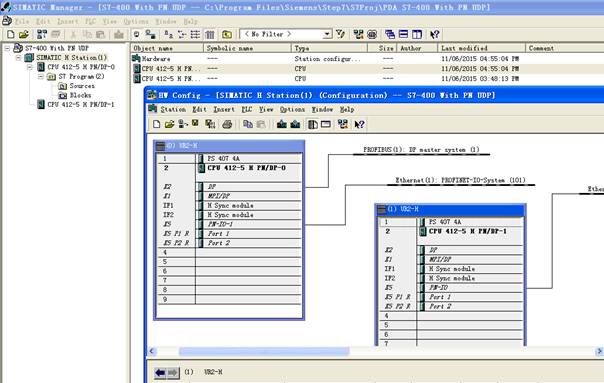

DB1000.StringA[1],// CH1 L,1,, T,DB1000.IntA[1],// DB1000.IntA[1],// CH2 L,2,, T,DB1000.IntA[2],// DB1000.IntA[2],// CH3 …… AN,M1.6,, =,DB1000.BoolB[15],// DB1000.BoolB[15],// CH73 AN,M1.7,, =,DB1000.BoolB[16],// DB1000.BoolB[16],// CH74 11.2 S7-400 Redundant PLC configuration

UR2-H Redundant frame is needed.

if the Ethernet port is not available after power on, It will be normal if you wait 20 minutes.

11.3

CPU with integrated PN port(S7-300/400)

UDP communication protocol is used, the type of data source is 25, which supports the following or higher version CPU.

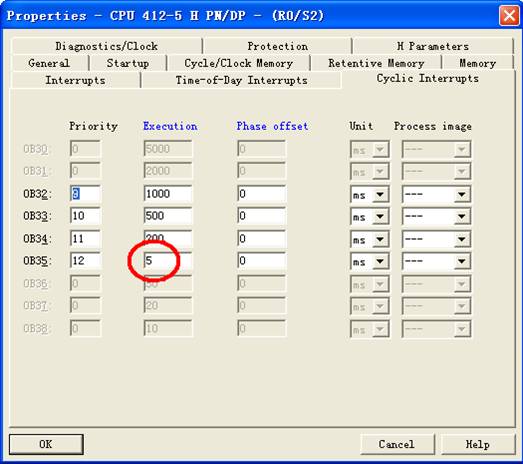

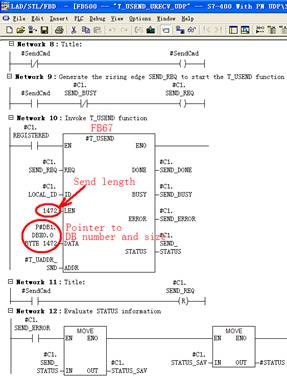

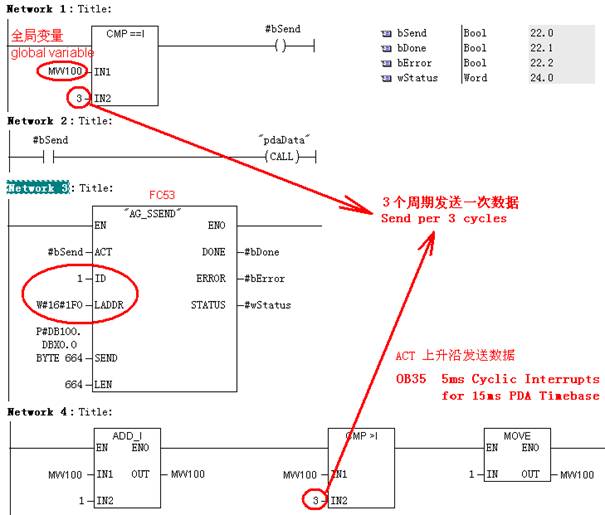

Please ask for the example of the collection process "PDA S7-400 With PN UDP.rar" if needed, Multiple connections can be created in one CPU. The following is configuration and program for collection of 1472 bytes, 10ms sampling period, rising edge triggered, OB35 program cycle is set to 5ms.

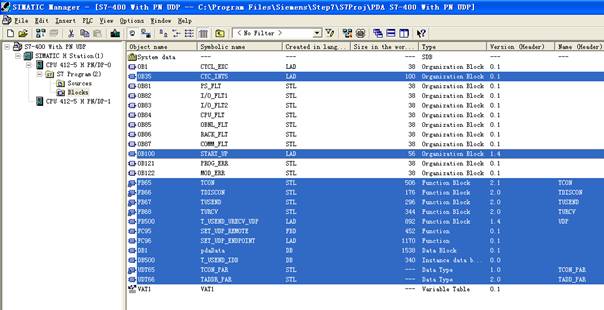

Copy OB35, OB100, FB65, FB66, FB67, FB68, FB500, FC95, FC96, DB1, DB500, UDT65, UDT66 to user’s program, FB65, FB66, FB67, FB68 are system function blocks, rename the block with name conflict.

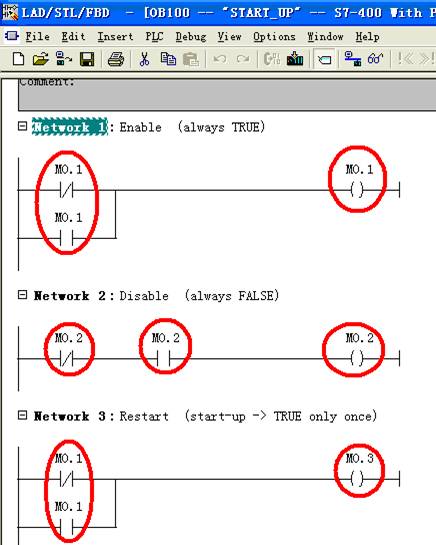

PDA program use 3 global BOOLs, M0.1, M0.2 and M0.3 are used in this example, DB1 is the data to be collected. OB100 procedures are as follows.

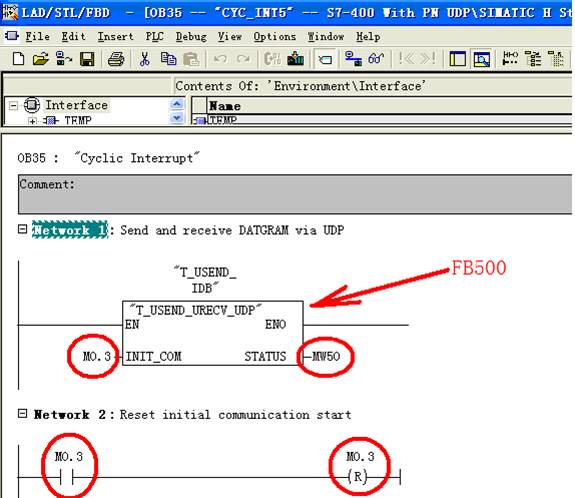

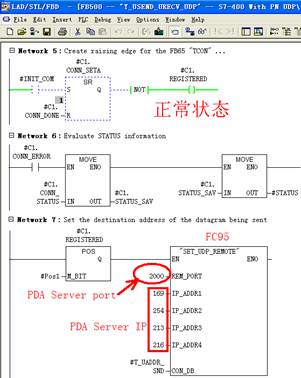

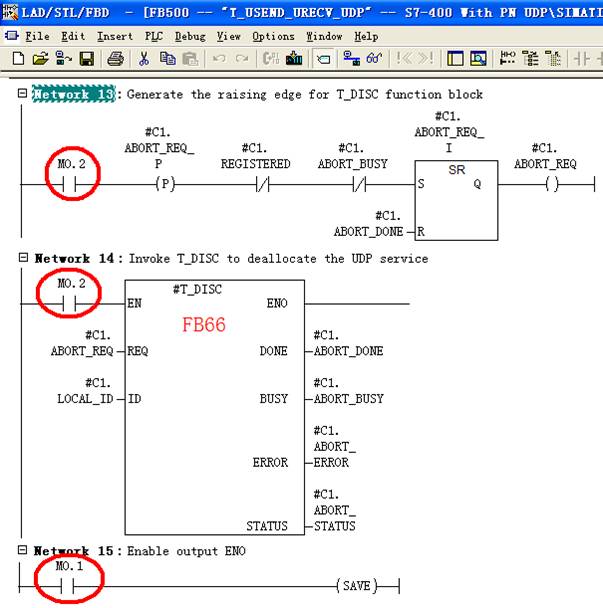

OB35 procedures are as follows.

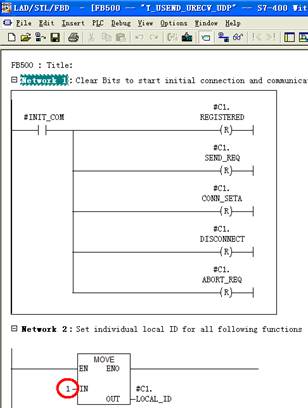

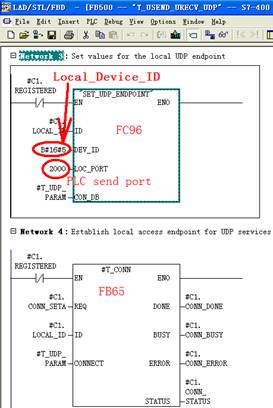

FB500 procedures are as follows.

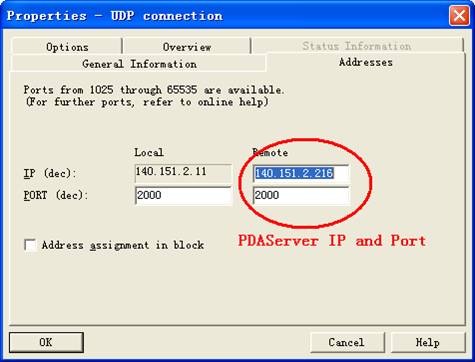

LOC_PORT must be same as REM_PORT.

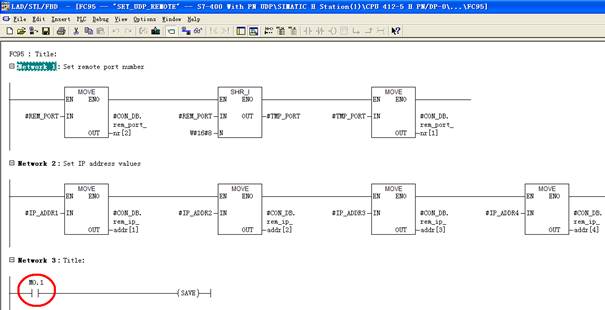

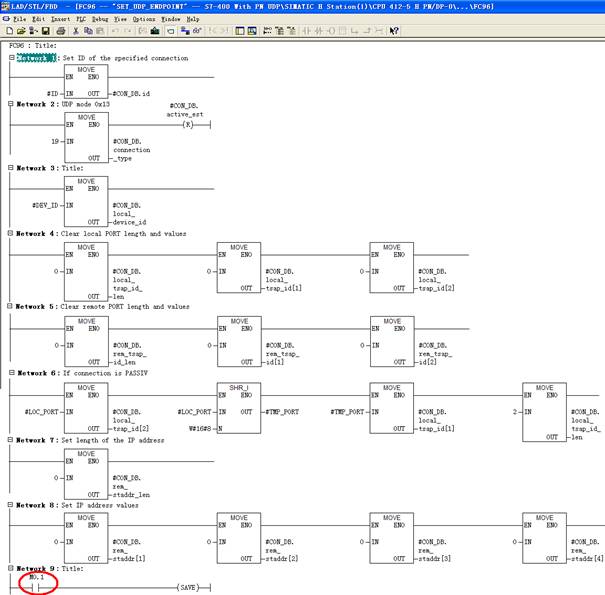

FC95 procedures are as follows.

FC96 procedures are as follows.

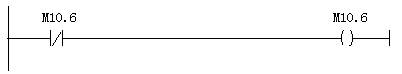

Place the below ladder to a

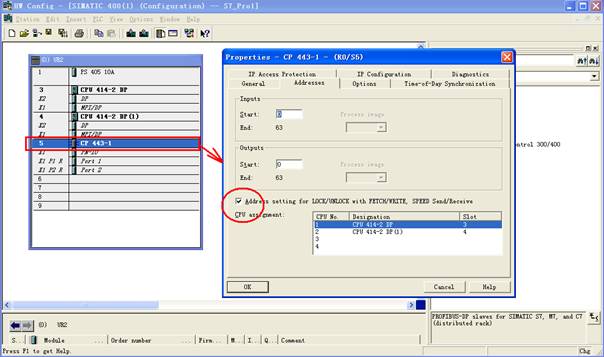

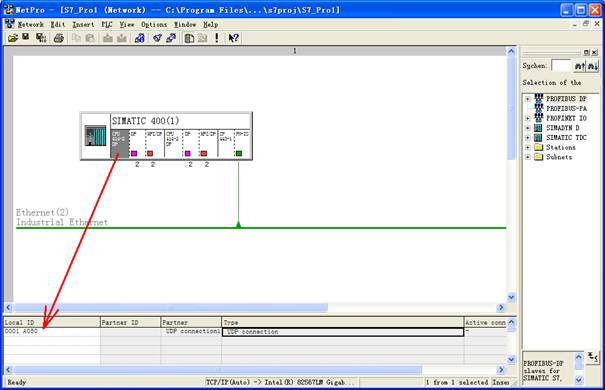

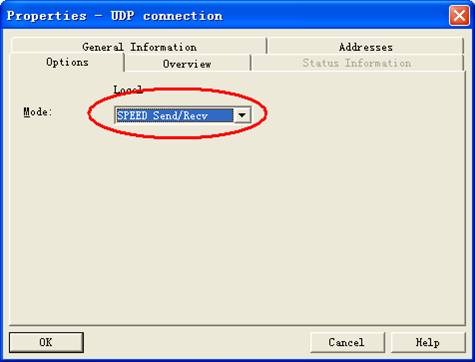

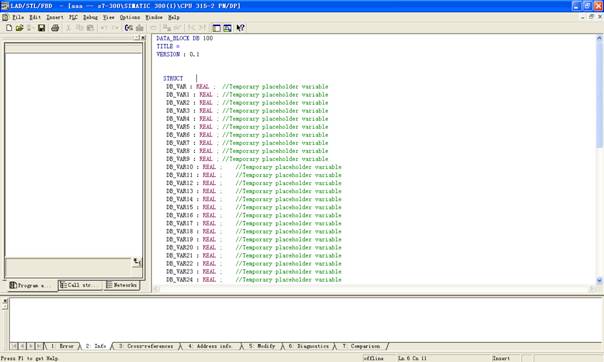

11.4 6GK7 343/443-1EX20-0XE0 and above Ethernet cardUDP communication protocol is

used, Each connection can collect at most 1452bytes, Sampling period is about

10~20ms, the other CPU in the same rack besides the first send data to CPU1, CPU1

collects data together, see Network adapter property settings.

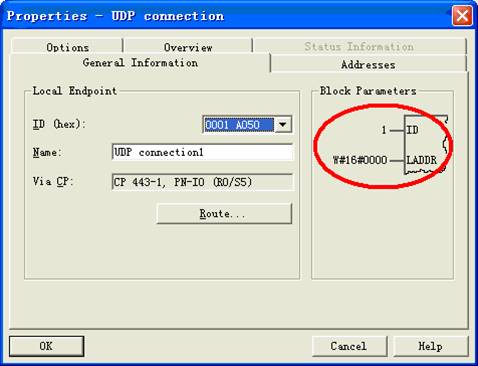

Connection property settings.

PLC procedures are as follows, FC53 is used to send data.

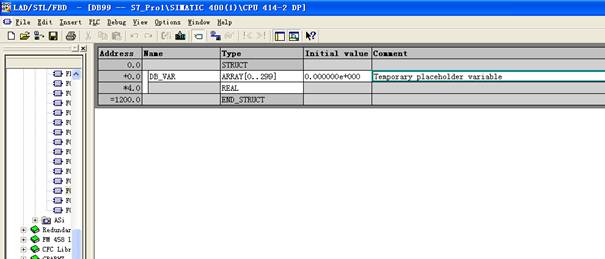

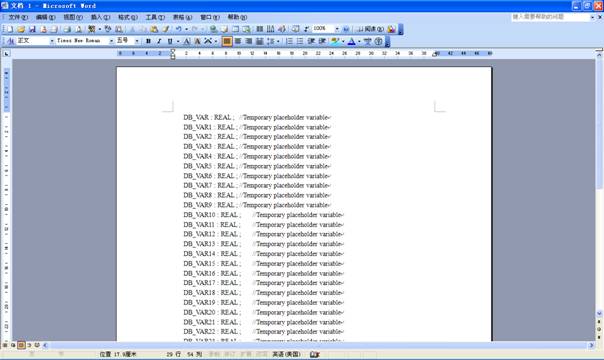

DB99 defines 300 REAL.

PDAServer configuration for 300REAL/10ms is as follows, pay attention to swap byte. [2000,300CH,10.000ms,192.168.0.100,25S,Note,192.168.0.216] No,

Name,Adr/note,Unit,Len,Offset

,Gain

,Type,ALM, CH1=, ,

, ,4 ,0.000000,1.000000,REAL,0 ,0.000,0.000,0.000,0.000,0 , CH2=, ,

, ,4 ,0.000000,1.000000,REAL,0 ,0.000,0.000,0.000,0.000,0 , CH3=, ,

, ,4 ,0.000000,1.000000,REAL,0 ,0.000,0.000,0.000,0.000,0 , CH4=, ,

, ,4 ,0.000000,1.000000,REAL,0 ,0.000,0.000,0.000,0.000,0 , CH5=, ,

, ,4 ,0.000000,1.000000,REAL,0 ,0.000,0.000,0.000,0.000,0 , CH6=, ,

, ,4 ,0.000000,1.000000,REAL,0 ,0.000,0.000,0.000,0.000,0 , …… CH300=, , , ,4 ,0.000000,1.000000,REAL,0 ,0.000,0.000,0.000,0.000,0 , The Tcp protocol is similar. In order to ensure the data consistency, the pdaData function block is located before the transmission function block. The hardware address of PIxxx PQxxx from DP network should not be put into the pdaData which prevent CPU failure due to DP and other network disconnection, they may be converted in OB1. With the increase of the

number of PLC Ethernet communication connections or the amount of communication,

the transmission speed and the number of bytes used for PDA communication

will slow down and decrease. please select Profinet mode to collect more data

or for less collection cycle, see section 4.7 for detail, Application

example: slab yard and heating furnace area of some 11.5

6GK7 343/443-1EX11-0XE0 and the following Ethernet cards

Udp protocol: S7-PLC directly send data block to PDA server by FC5 or FC50(>240bytes), the network configure is below, the other is same as section 4.3.

Tcp protocol: S7-PLC directly send data block to PDA server by FC5 or FC50 (>240bytes), S7-PLC acts as tcp client, the network configure is below, the other is same as section 4.4.

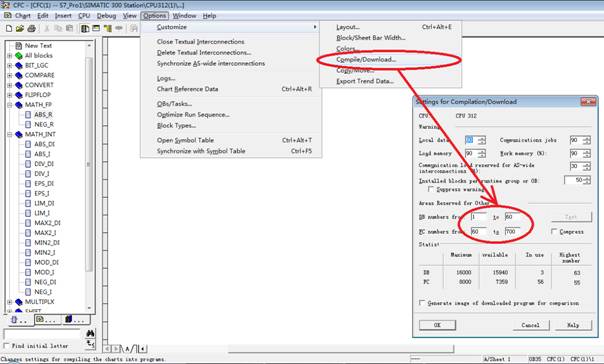

11.6

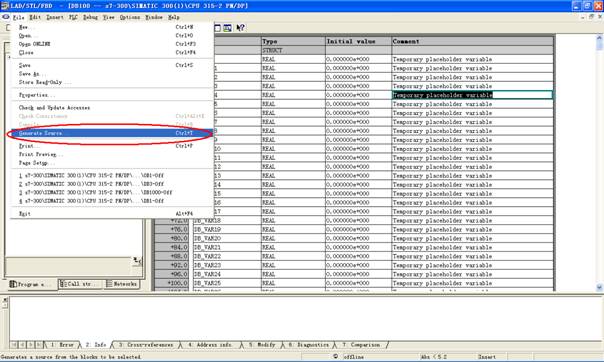

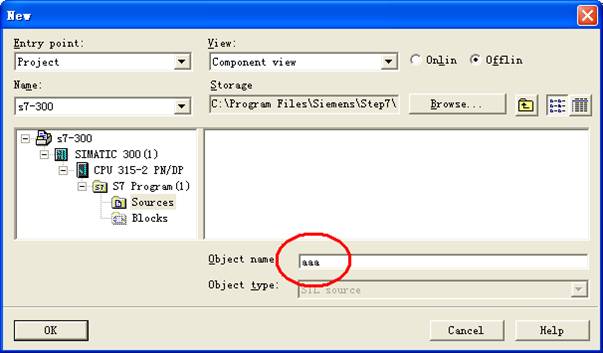

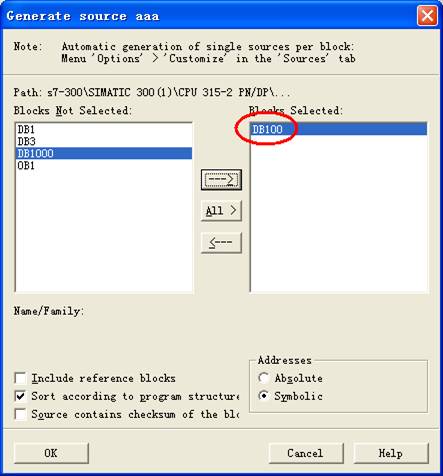

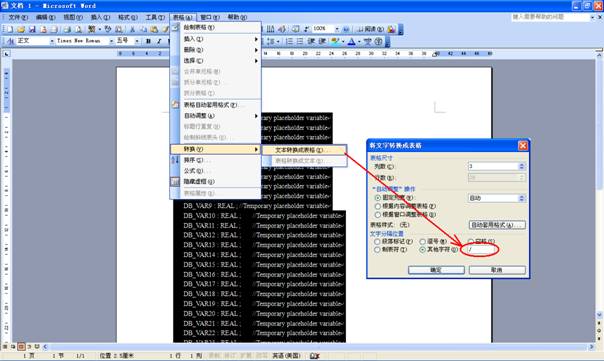

Export comment of S7 DB block to grid

11.7 CFC programming notesLAD programming is used by the PDA FC block, there will be a mixed programming of CFC and LAD if the user main program is CFC, S7-PLC supports this way, the PDA blocks effective range should be paid attention to, see below, otherwise they will be covered when CFCs are compiled or cause system conflict, More memory space is occupied because a large number of DB and FC are produced after CFC are compiled, to ensure CF card is sufficient to no compression program for download, otherwise "The interface of block has changed Please reimport" error will appear when you download CFC, you may decrease the PDA FC block number, it is priority to be downloaded to the CF card, the error may be not appeared, To replace CF card with large capacity is the fundamental solution.

11.8

About "upload"

The address related to Id may

be changed when PLC Ethernet network configuration is uploaded, so the

project configuration should be consistent with the actual PLC hardware, Do

not have to use the upload network configuration. |

|||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||

|

Apparatus test&Fault diagnosis&Quality analysis |

Millisecond data sampling Real-time data compression Capture signal instantaneous mutation |

||||||||||||||||||||||||||||||||

|

友情链接 百度 腾讯 新浪 网易 搜狐 凤凰 淘宝 京东 中国自动化网 中国工控网 西门子 罗克韦尔 华军软件园 天空软件站 非凡软件站 多多软件站 携程 知乎 中国五矿 中冶集团 中冶赛迪 中冶南方 中冶京诚 中冶华天 中冶长天 中冶北方 中冶焦耐 中国宝武 宝信 宝钢 武钢 鞍钢 河钢 首钢 鄂ICP备2025092850号 版权所有©Copyright:2025-2035. 经纬铭月科技(武汉)有限公司 |

|||||||||||||||||||||||||||||||||

Develop communication protocol, Customized

analysis function, XinChuang domestic obsession

PDAServer

PDAClient