|

Profinet EIP EtherCAT

EGD UDP RFM RtEthernet Tc-net S7 Modbus OPC iso Ads Siemens

AB,GE,Mitsubishi,Beckhoff,MOOG,Schneider,ABB,Alstom,Driver,Domestic

PLC,Special Board QDR quality data

recording (digital steel coil) centimeter and millisecond level, supports

32+clients online Equipment testing, fault

diagnosis, quality analysis, ikoPDA CHPDA PLC-PDA, No crack & call

similar system |

3rd PDA formats &

Rich proprietary features Global Standards,

Exceptional Value Simplified for Full Customization &

OEM with Open APIs Proven by Hundreds of |

||||

|

Process Data

Acquisition – PDA -- Detailed analysis of

quality manage & industrial big data sources -- Full stack develop & Fully intellectual property

owned |

|||||

|

46 |

|||||

|

47 |

|||||

|

56 PDA system scheme for converter, RH furnace, LF furnace in

steel plant |

|||||

|

64 S7-1200 as

both a PROFINET IO Controller and an IO Device |

|||||

36

Auxiliary transmission S120

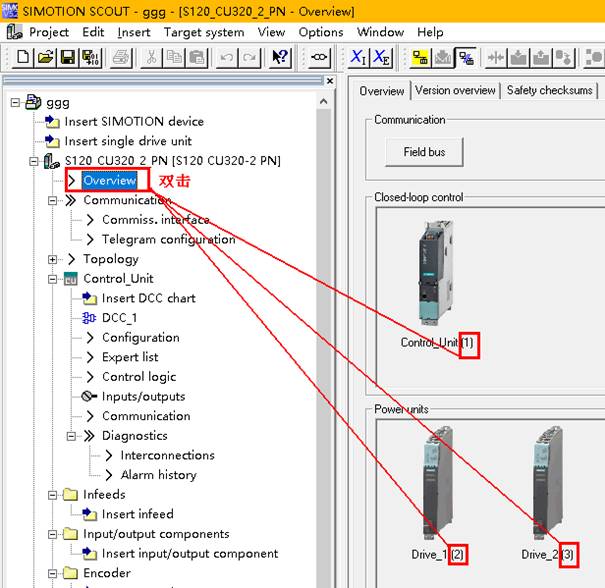

S120 is a new generation frequency converter launched by Siemens, with DP and PN interfaces. CU320-2 PN (control unit 6SL3 040-0MA01-0AA0+memory card 6SL 3054-0EJ01-1BA0), CU320 (control unit 6SL3 040-0MA00-0AA1+memory card 6SL 3054-0CG00-1AA0). 36.1

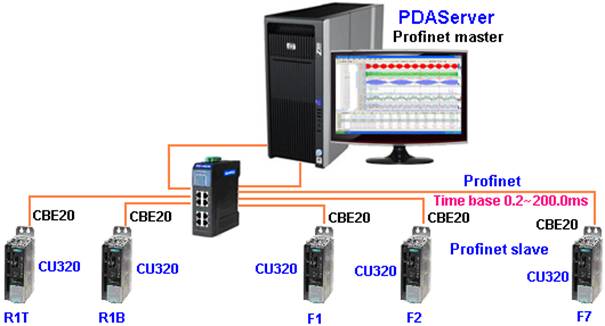

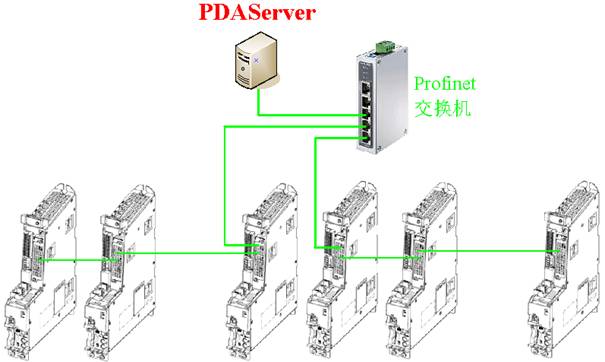

PDAServer as Profinet master

PDAServer, as Profinet master station, can collect data from several CU320 slave stations at high speed. this is the fastest way to collect data without interference from A/D and D/A conversion. the data source type is 40. You may use the CU320 self PN port or add CBE20 network card, the speed is lower than self PN.

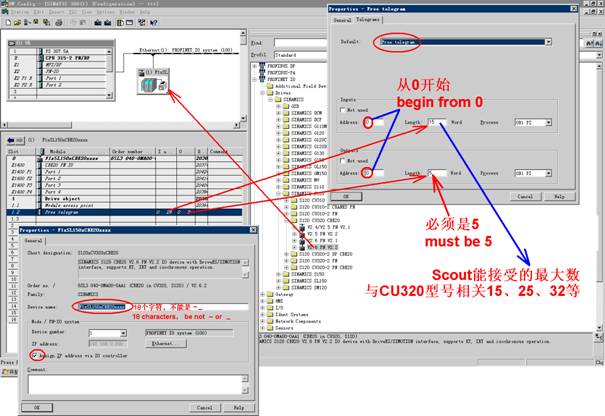

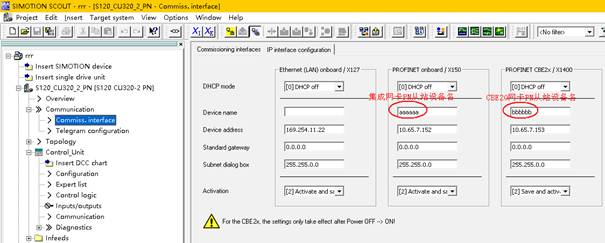

The CPU 315-2 PN/DP hardware configuration can be referred to in the following figure.

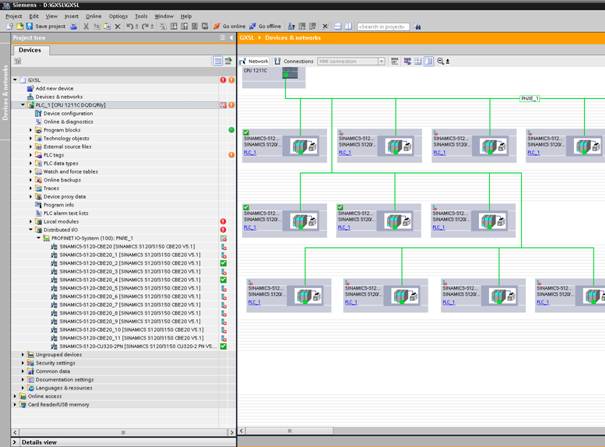

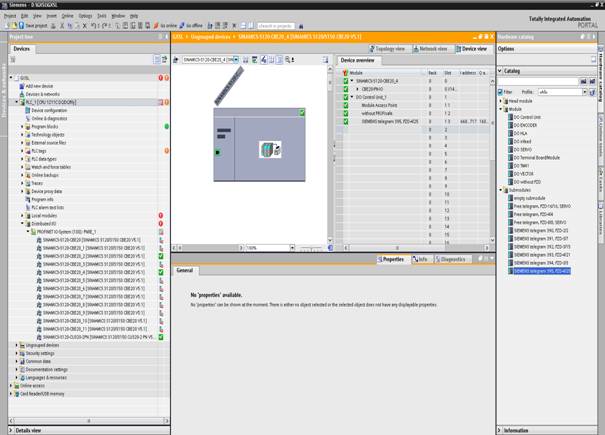

The hardware configure of

devices and networks is below in CPU

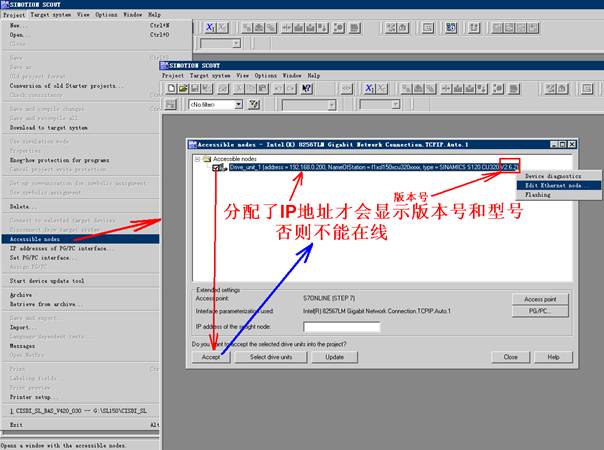

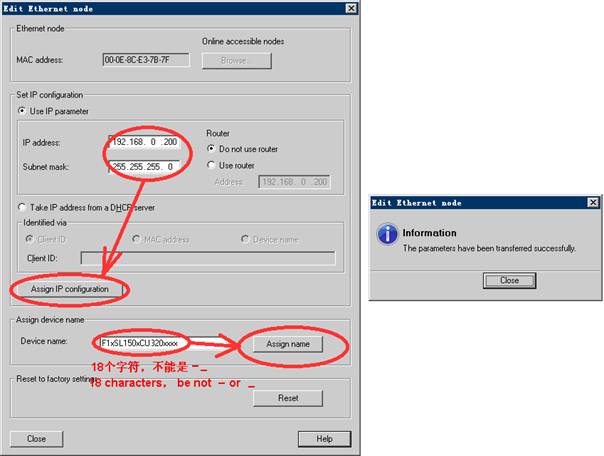

View version number and assign

IP address and Profinet device name to CU

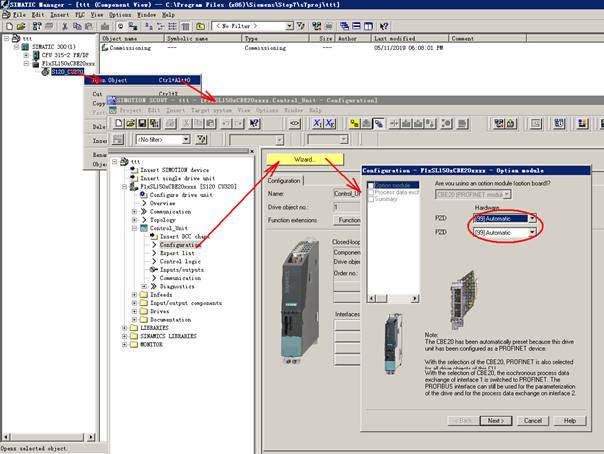

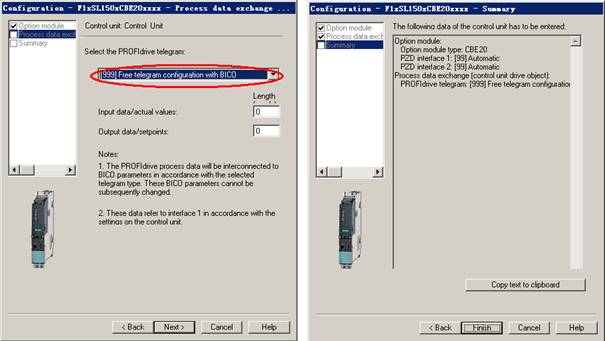

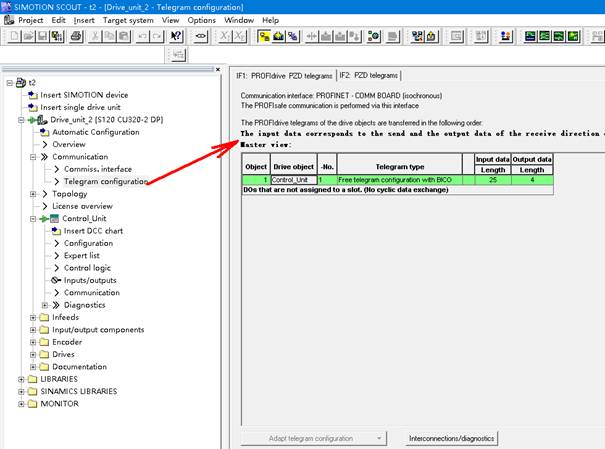

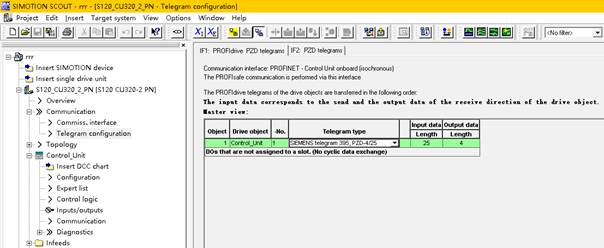

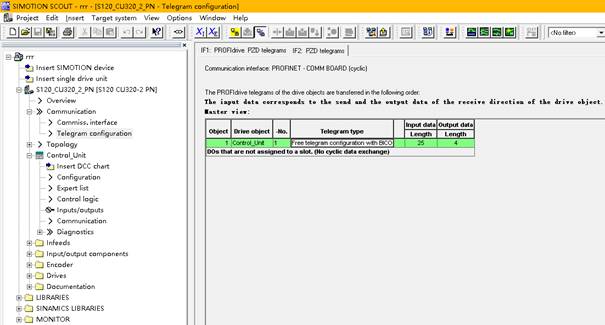

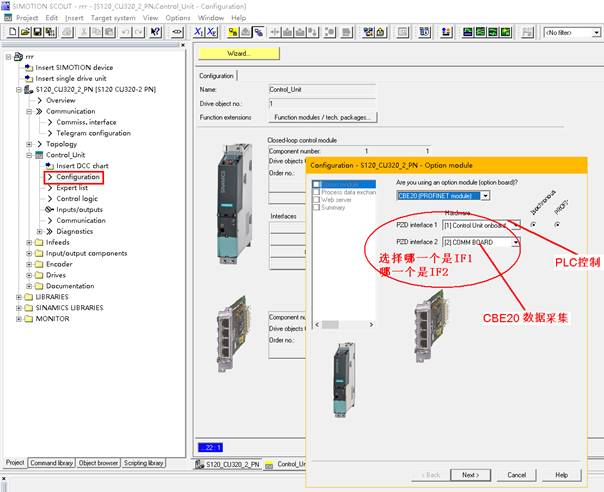

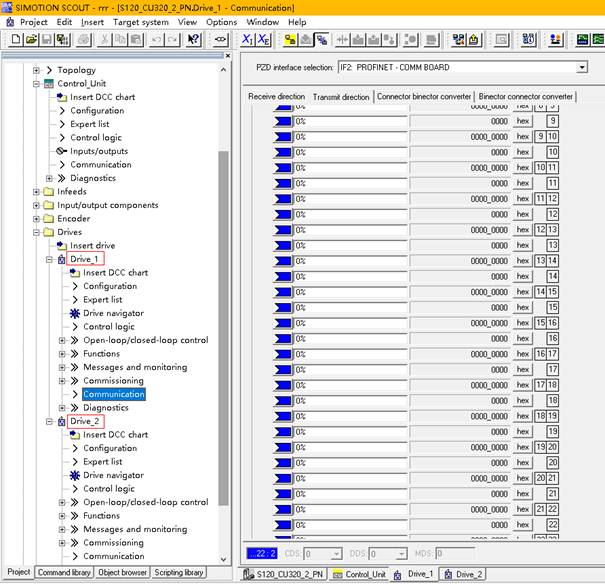

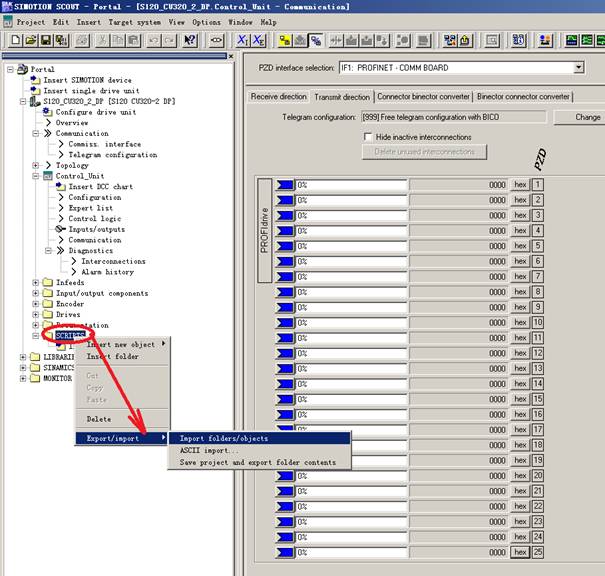

The configuration in Scout is as follows:

CBE20 is automatically allocated to IF1, DP is automatically allocated to IF2, DP is automatically allocated to IF1 if CBE20 is not inserted.

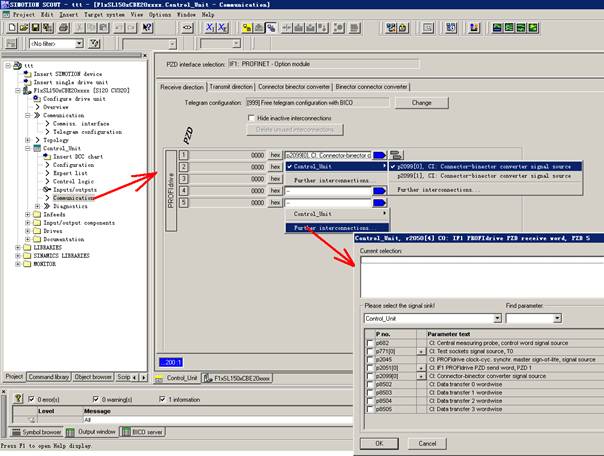

To configure the data to CU320 sent by PDAServer.

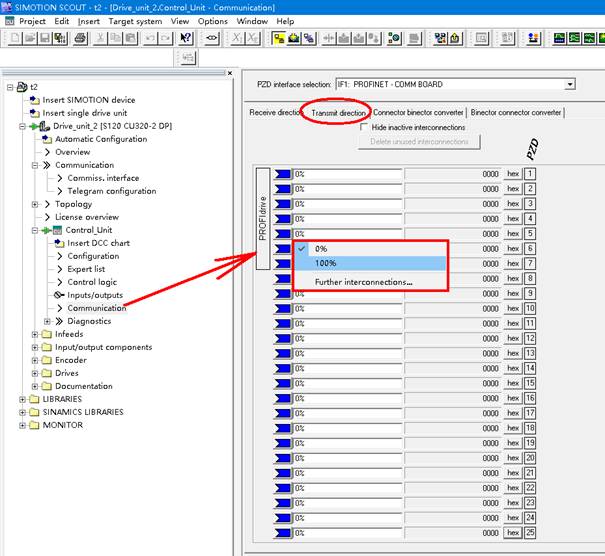

To configure the data to PDAServer sent by CU320.

36.2 PDAServer

as Profinet Master Station Bus Time Division Multiplexing

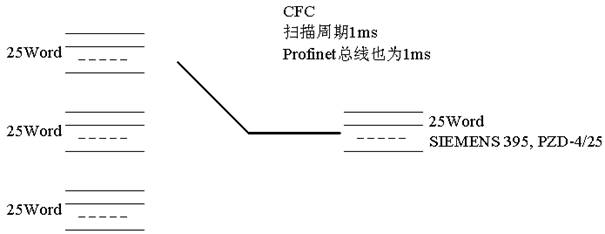

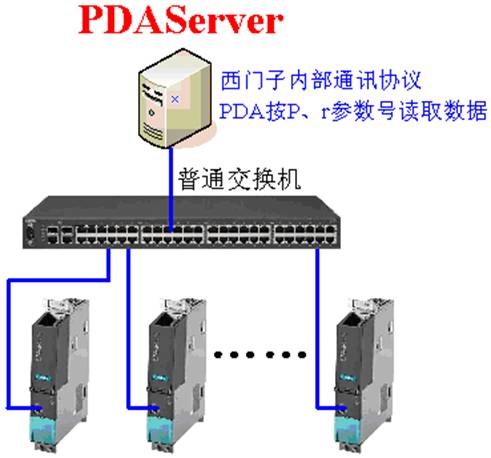

Add Ethernet board CBE20 to each CU320 to form a dedicated data collection PN network. Indicator: CU: 25Word, Supply: 10Word ±, each Drive: 20Word ±, data refresh cycle up to 1 millisecond, Profinet bus time division multiplexing method can collect more data, (CU: 25Word, Supply: 10Word ±, each Drive: 20Word ±) * 3 data refresh cycle up to 3 milliseconds. Advantages: Fast collection speed, no modification required for automated L1 software, isolated from the automated L1 system. Disadvantages: CU320 requires the addition of CBE20, CU320 parameters need to be modified, and separate networking is required.

The following figure shows the CFC program diagram for collecting CU: 75Word with a PDA side data refresh cycle of 3 milliseconds. If CU only collects 25Word, there is no need for the CFC program.

36.3

Transfer the CU320 data to PLC or D455

As a DP or PN slave station, CU320 transmits data to the master station, and the master station collects data, the comprehensive acquisition speed is slower than that of the previous scheme. 36.4

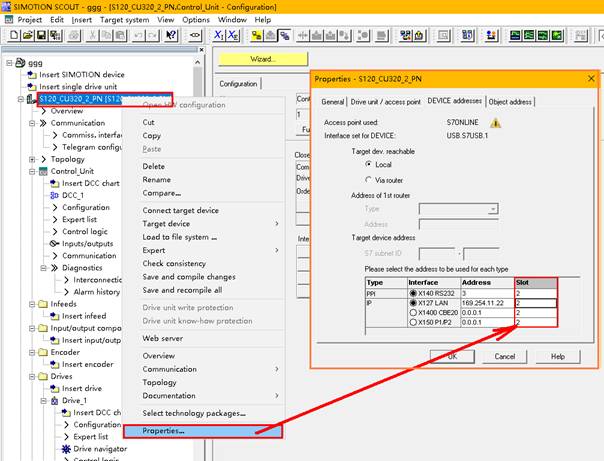

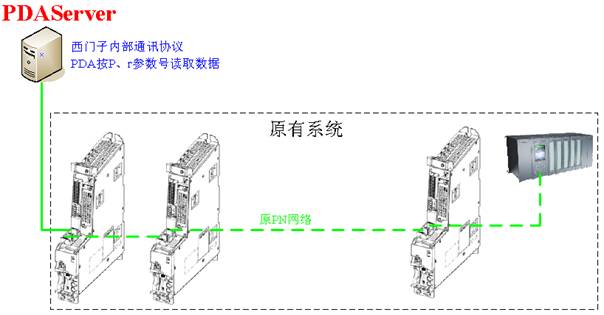

PDAServer reads directly by r or p parameter address

The data source type is 27 or 21, and the comprehensive collection speed is slower than the previous two schemes, but it is convenient. The CPU slot number is determined as shown in the following figure.

Rules for setting variable addresses: DB [parameter number] DBB [1024 * device number+parameter index] corresponds to int8 and uint8 DB [parameter number] DBW [1024 * device number+parameter index] corresponds to int16 and uint16 DB [parameter number] DBD [1024 * device number+parameter index] corresponds to int32, uint32, and float The device number is determined as shown in the following figure. Parameter subscripts refer to the subscripts of array elements, such as 0, 1, 2, 3, etc. In a PDA connection, the same array can only have one of its elements. To read multiple elements of the same array, multiple PDA connections must be established.

Method 1: Use the PN network composed of existing X150 to read the P and r parameters. Indicator: Read 50 parameters with a refresh cycle of approximately 10 milliseconds. Advantages: Hardware and network, L1 software, and CU320 parameters do not require any modifications.

Method 2: X127 monitoring port networking, reading P and r parameters through the monitoring port. Indicator: Read 50 parameters with a refresh cycle of approximately 10 milliseconds. Advantages: The automated L1 software does not require any modifications. Disadvantage: The IP of the CU320 monitoring port needs to be modified and networked.

36.5 Comprehensive

data acquisition plan for company level main and auxiliary transmission

systems

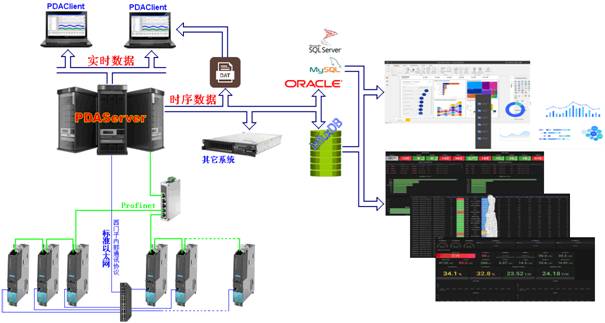

In order to isolate from the automated L1 system, signals with a sampling period of less than 10ms are collected through a dedicated PN network formed by CBE20. If there are no special requirements for the sampling period, data is read from S120 through standard Ethernet using Siemens internal communication protocol. The PDA system saves the collected signals as. dat files and can also be saved to relational and temporal databases such as InfluxDB, making it convenient for various automatic reports and big data analysis such as Power BI, Sailsoft, and Grafana. Multiple PDA servers need to be set up based on the geographical location of each branch and the number of transmission systems.

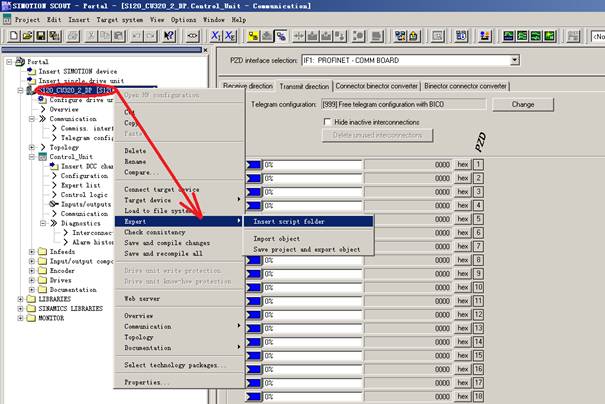

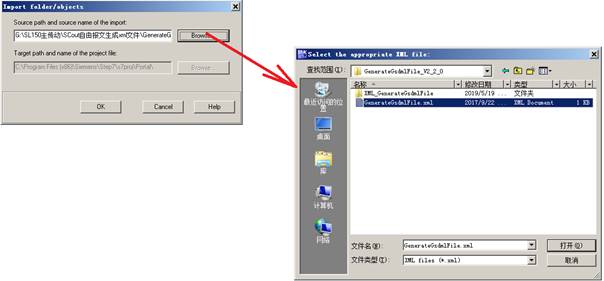

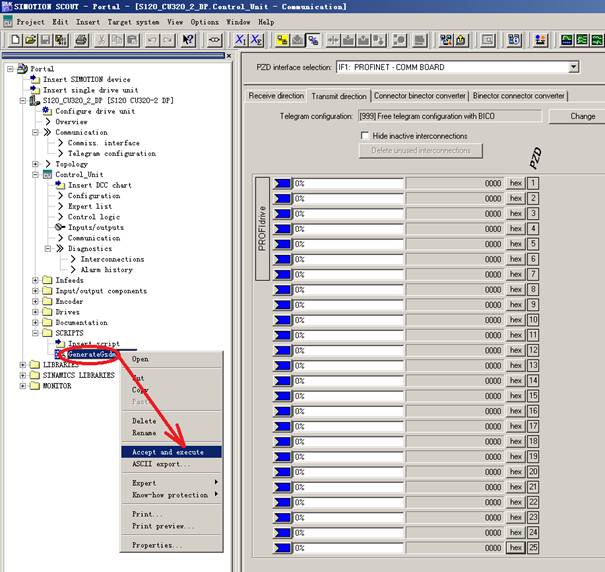

36.6 Method

of Importing Scout Free Messages in Portal

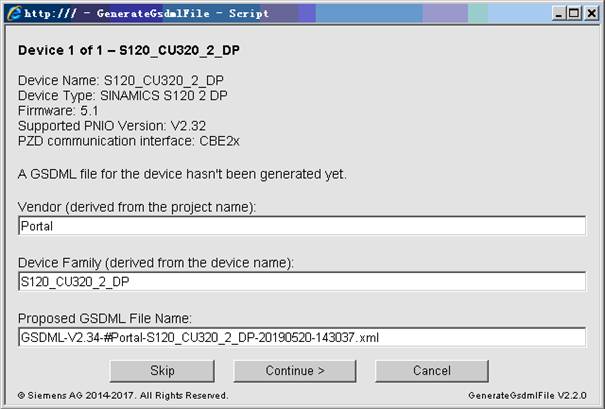

The onboard PN port X150 serves as IF1 to communicate with automation L1, while CBE20 serves as IF2 to communicate with PDA. Free messages are used for communication with PDA. If there are no free messages in the chart, the configured IF2 communication messages need to be exported as gsd from Scout. Since Scout can only export IF1, IF1 and IF2 should be exchanged first. After the following operations are completed, the settings of IF1 and IF2 should be restored. Prepare two sets of files, such as GenerateGsdmlFile_ V2_ 2_ 0 and GSDML-V2.34-Siemens Sinamics_ S_ CU3x0-20181115.xml.

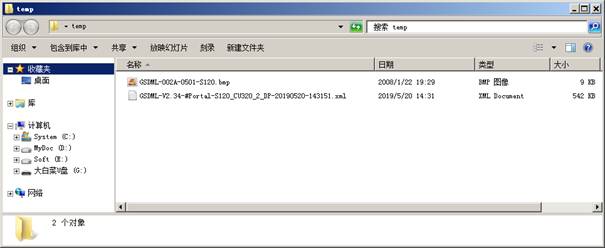

Finally, generate these two files.

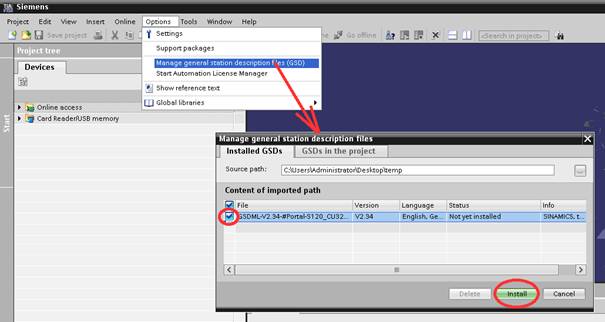

Load in Portal.

|

|||||

|

|

|||||

|

Apparatus test&Fault diagnosis&Quality analysis |

Millisecond data sampling Real-time data compression Capture signal instantaneous mutation |

||||

|

友情链接 百度 腾讯 新浪 网易 搜狐 凤凰 淘宝 京东 中国自动化网 中国工控网 西门子 罗克韦尔 华军软件园 天空软件站 非凡软件站 多多软件站 携程 知乎 中国五矿 中冶集团 中冶赛迪 中冶南方 中冶京诚 中冶华天 中冶长天 中冶北方 中冶焦耐 中国宝武 宝信 宝钢 武钢 鞍钢 河钢 首钢 鄂ICP备2025092850号 版权所有©Copyright:2025-2035. 经纬铭月科技(武汉)有限公司 |

|||||

Develop communication protocol, Customized

analysis function, XinChuang domestic obsession

PDAServer

PDAClient