|

Replace the import

of PDA and Analyzer tools 30+ Live Clients

Supported, Numerous unique features Apparatus

test&Fault diagnosis&Quality analysis Compatible with

third-party PDA file formats |

Rivals top-tier

PDA system at a fraction of the cost Optimized for

Chinese user habits, installation-free convenience Support customized

functions, OEM, Fully open data interfaces Hundreds of

projects for large enterprises |

||||

|

Process Data Acquisition – CHPDA -- Detailed

analysis of quality manage&industrial big data sources |

|||||

|

56 PDA

system scheme for converter, RH furnace, LF furnace in steel plant |

|||||

|

64 S7-1200 as both a PROFINET IO Controller and an

IO Device |

|||||

|

65 |

|||||

|

66 |

|||||

|

67 |

|||||

|

68 |

|||||

|

69 |

|||||

|

70 |

|||||

|

71 |

|||||

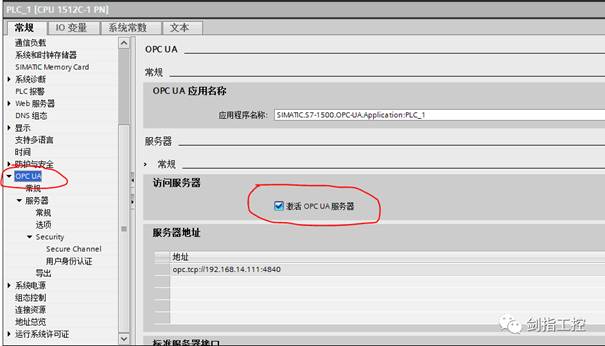

47 Collecting

S7-1500 data through Opc Ua

The core of the OPC communication standard is interoperability and standardization issues. Traditional OPC technology effectively solves the interoperability problem between hardware devices at the control level, and communication standardization at the enterprise level is also necessary. The previous access specifications for OPC UA were based on Microsoft's COM/DCOM technology, which would bring irreparable weaknesses to the communication at the new level. In addition to the increasingly prominent issues of insufficient flexibility and platform limitations in traditional OPC technology, the OPC Foundation has released the latest unified data communication method - OPC Unified Architecture (OPC UA), covering different aspects of OPC Real Time Data Access Specification (OPC DA), OPC Historical Data Access Specification (OPC HDA), OPC Alarm Event Access Specification (OPC A&E), and OPC Security Protocol (OPC Security), But functional extensions have been made on top of it. OPC UA is another breakthrough after the great success of traditional OPC technology, making data collection, information modeling, and communication between the factory and enterprise levels more secure and reliable. Several advantages of OPC UA: (1) Platform independent, can run on any operating system (2) Prepare for future advanced systems and continue to be compatible with retained systems (3) More convenient configuration and maintenance (4) Service based technology (5) Increased visibility (6) Wider communication range (7) Improved communication performance In the era of Industry 4.0, communication between enterprise level information networks and industrial automation systems plays a crucial role. The flexibility and openness of OPC UA will enable it to play a greater role. In the future, OPC UA will also be adopted by more and more people in enterprise communication. OPC UA communication is cross platform, with higher security and reliability, meeting the needs of highly connected enterprise information. The S7-1500 supports the functionality as an OPC UA server starting from V2.0. Activate OPC UA server function: Open the OPC UA option of the CPU, check Activate OPC UA server, and enable the SIMATIC server standard interface (set the maximum number of connections and port numbers as needed).

Enable server certificates, activate security policies, and add trusted clients.

Enable user identity authentication, where you can choose between visitor access or username access, which will be used for setting the client.

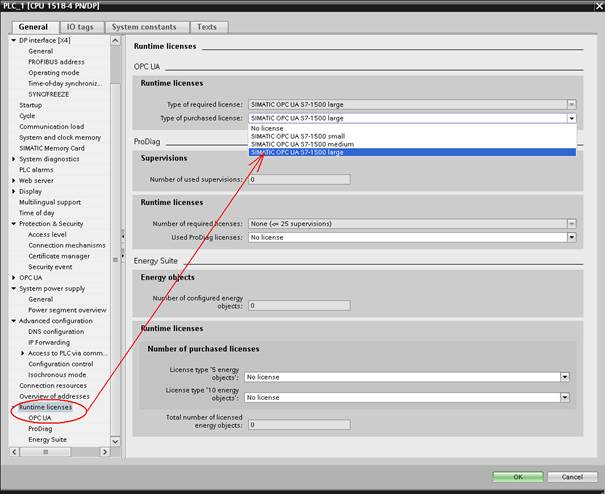

The license settings are shown in the following figure.

As the final step, the DB block must check 'DB can be accessed from OPC UA', otherwise it cannot be accessed.

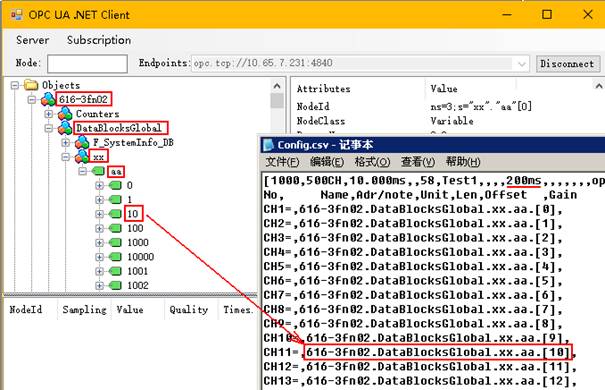

The rest are similar to the previous section. The corresponding relationship between Opc Ua's point names and PDA's point names is shown in the following figure, with each level separated by "." and the array subscript enclosed by "[" "]". The multidimensional array is shown in [2,3,2]. 200ms in the figure below is the minimum sampling interval time of Opc Ua in PLC, which should be consistent with the setting in PDA and PLC.

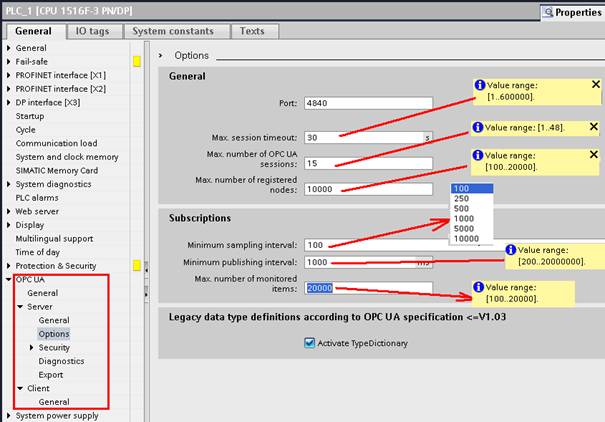

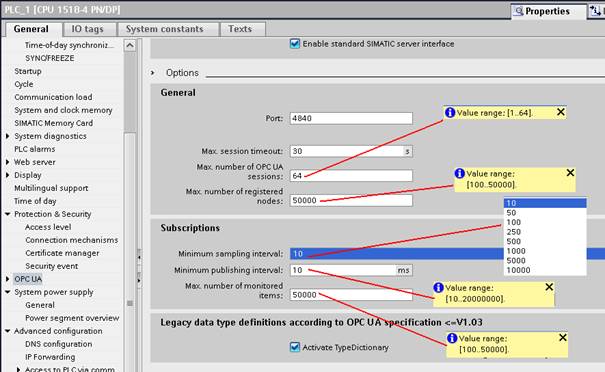

Each type of PLC provides

different Opc Ua access points and sampling cycles based on its own

performance. The following figure shows some limit values for S7

The limiting parameters of S7-1518-4 PN/DP are shown in the following figure.

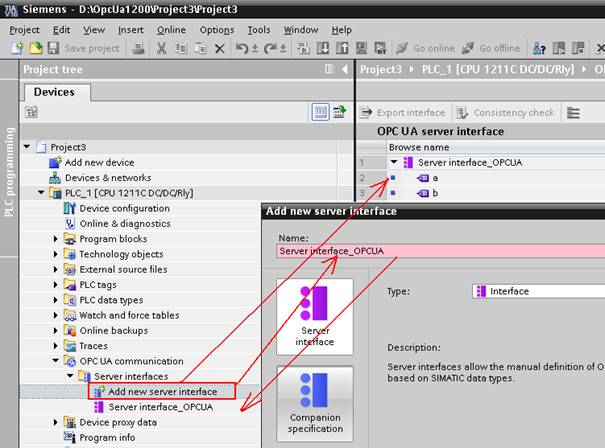

S7-1200 needs to add Server interfaces for Opc Ua communication in OPC UA communication, and drag variables to be accessed through Opc Ua to this interface, with limited points.

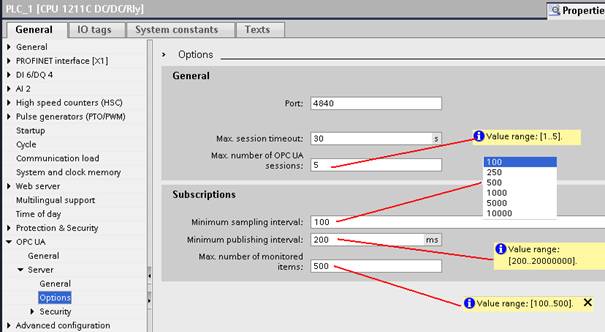

The limiting parameters of S7-1211 are shown in the following figure.

|

|||||

|

|

|||||

|

Apparatus test&Fault diagnosis&Quality analysis |

Millisecond data sampling Real-time data compression Capture signal instantaneous mutation |

||||

|

友情链接 百度 腾讯 新浪 网易 搜狐 凤凰 淘宝 京东 中国自动化网 中国工控网 西门子 罗克韦尔 华军软件园 天空软件站 非凡软件站 多多软件站 携程 知乎 中国五矿 中冶集团 中冶赛迪 中冶南方 中冶京诚 中冶华天 中冶长天 中冶北方 中冶焦耐 中国宝武 宝信 宝钢 武钢 鞍钢 河钢 首钢 沙钢 山钢 涟钢 鄂ICP备2025092850号 版权所有©Copyright:2025-2035. 经纬铭月科技(武汉)有限公司 |

|||||

Develop communication protocol, Customized

analysis function, XinChuang domestic obsession

PDAServer

PDAClient